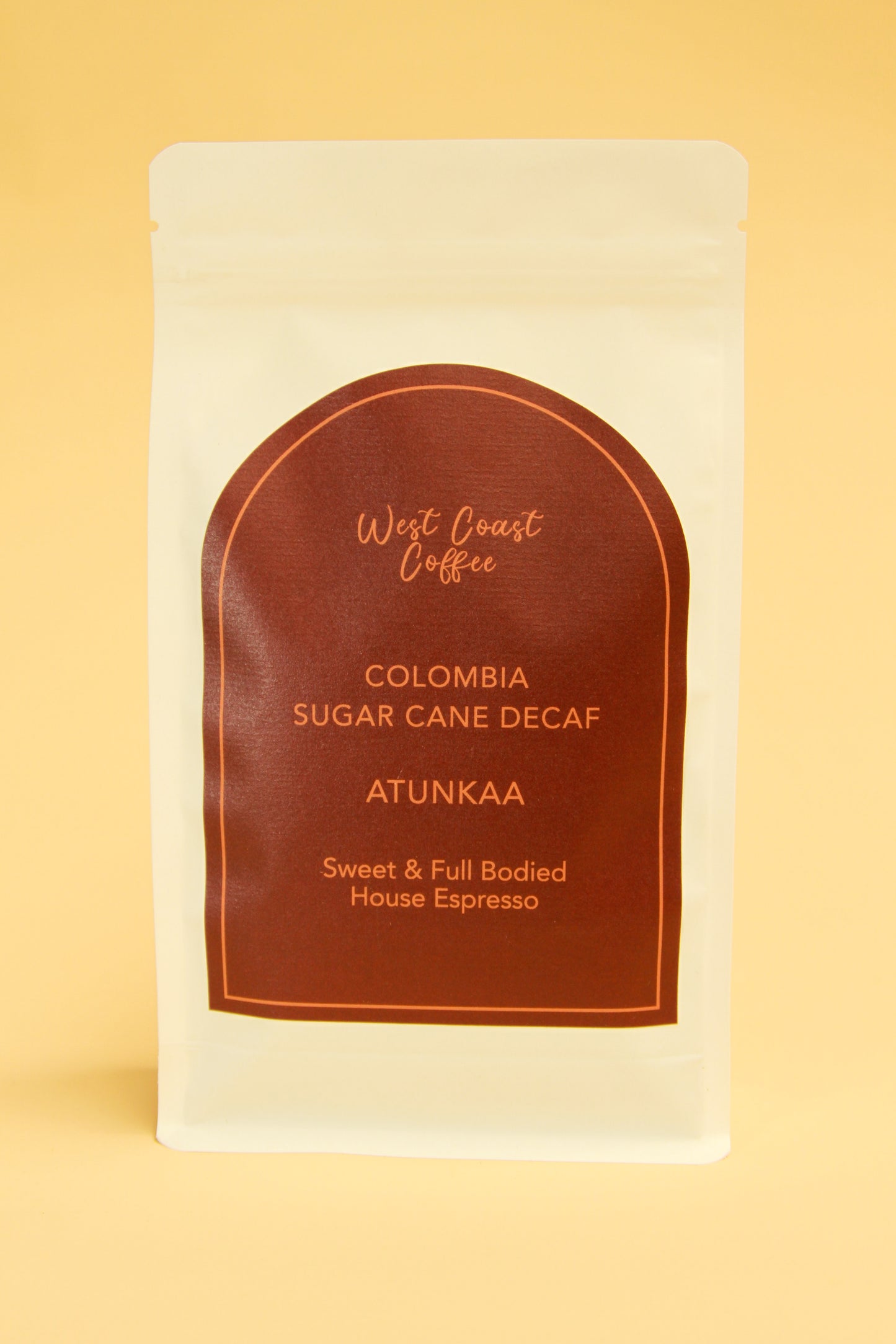

West coast coffee roasters

Atunkaa Colombian Decaf

Atunkaa Colombian Decaf

Couldn't load pickup availability

Shipping

Shipping

Royal Mail Postal service

(Tracked 48 Hour)

Atunkaa Colombian Decaf

Tasting Notes

Sweet & Full Bodied House Espresso

Location - Colombia

Region - Toribio, Tacueyó, and San Francisco

Producer - Multiple smallholder farms

Exporter - Siruma Coffee

Importer - Falcon Coffee

Process - Sugar Cane Decaf

Varietal - Castillo & Colombia

Altitude - 1700 - 1900 MASL

Cup Score - 85 (Falcon Coffee)

Producer Info

ATUNKAA

"Atunkaa" in the Wayuu dialect describes the state of sleeping or dreaming.

These sugarcane decaf lots are produced by our community of farmers from the regions of Cauca, Caldas & Tolima. They are processed with care to preserve the natural sweetness and complexity of their varieties.

About SICCET: This coffee comes from SICEET – the Asociación Indígena de Caficultores Especiales, Ecológicos de Toribio. This indigenous Nasa association is made up of smallholder families in Toribio, Cauca, Colombia, whose ancestral lands extend across Toribio, Tacueyó, and San Francisco. The farms sit at 1,700–1,900 metres above sea level, on volcanic soils nurtured by cool mountain air currents from the Cordillera Central. These conditions, combined with sustainable agroforestry practices, help cultivate coffees with caramel and citrus aromas and a soft, sweet flavour profile.

SICEET farmers grow specialty coffee in multiple forms – pergamino seco (dry parchment), roasted, and ground – following meticulous quality standards from seed to cup. Their varieties include Borbón Rosado, Colombia, and Castillo, with coffees classified into: Especial: premium lots with higher cupping scores and complex flavour profiles. Traditional / Conventional: traditional offerings with sweet, balanced notes. Cups often reveal aromas of citrus, fruits, nuts, caramel, and panela, with well-rounded body, sweetness, and acidity.

SICEET’s mission is to produce and commercialise high-quality coffees with dignity, in harmony with Madre Tierra, while supporting generational continuity and social well-being. Their vision is to be a leading example of sustainable coffee production, strengthening the social fabric of their communities while sharing their exceptional coffees with the world.